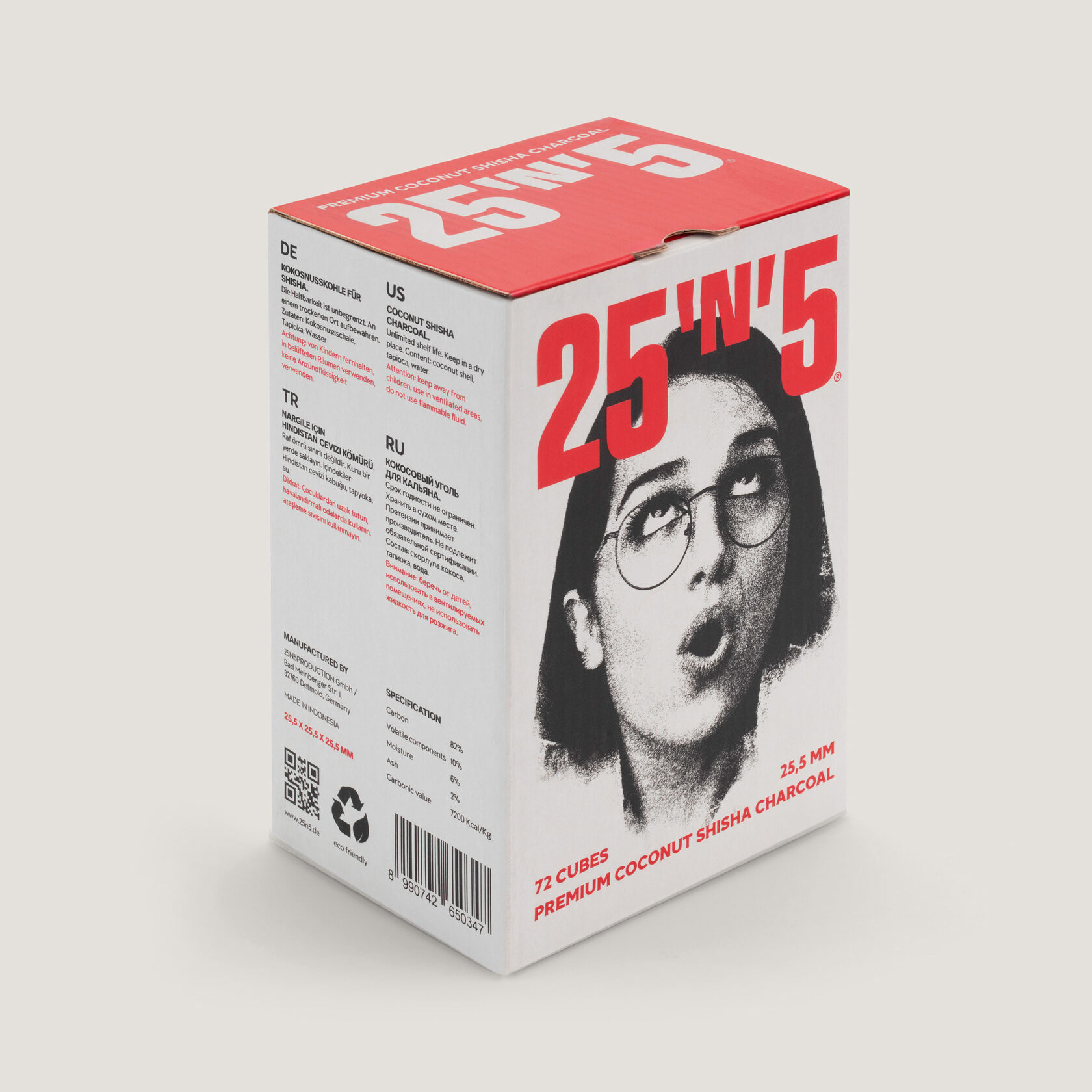

PREMIUM

COCONUT CHARCOAL

FOR HOOKAH

COCONUT CHARCOAL

FOR HOOKAH

ABOUT US

Despite the large number of brands of coconut charcoal for hookahs, the main problem for consumers is still the varying quality from batch to batch. To overcome this issue, we carefully select and test the quality of our raw materials and only send charcoal to our customers after testing it at our factory in Java, Indonesia.

The main parameters of these tests are:

The main parameters of these tests are:

ASH

CONTENT

CONTENT

The mass of ash remaining after the coal is completely burned should not exceed 2% of the weight of the coal.

THE STRENGTH

OF THE COAL

OF THE COAL

It should not split when heated and should withstand a fall from a height of 1 meter onto a hard surface in a hot state.

WORKING

TIME

TIME

The coal should allow you to smoke a hookah for at least an hour without replacing it.

We only send coal batches that have successfully passed these tests to our customers.

PRODUCTION

25N5 coconut shell charcoal is produced in Indonesia using only coconut shell without any additives. The raw material for our charcoal is 96% pyrolyzed coconut shell and 4% food-grade starch, which is used as an adhesive. To produce long-lasting charcoal, the raw material is well-pressed and dried in an oxygen-free oven. As a result, there is no odor during burning, and the charcoal does not affect the taste of tobacco.

PRODUCT SPECIFICATON

- Carbon: 82%

- Volatile content: max. 10%

- Moisture: max. 6%

- Ash content: max. 2%

- Calorific value: 7200 Kcal/kg

- Burning temperature: 700°

- Weight of 72 cubes:

1.06-1.10 kg

- Box weight:

ca. 12 kg

- Shelf life:

unlimited

- Cube size:

25,5 х 25,5 х 25,5 mm

ASSORTMENT

Discover the top-notch quality of 25N5 hookah charcoal and experience the true pleasure of smoking a hookah.

25N5PRODUCTION Gmbh / Bad Meinberger Str. 1, 32760 Detmold, Germany

MADE IN INDONESIA

© All Rights Reserved. 25n5.

MADE IN INDONESIA

© All Rights Reserved. 25n5.